Polypropylene Melt-Blown Filter Media

Melt-blown filter media by Handanhy had been engineered for consistent processing and excellent performance in stitched or ultrasonically sealed pleat filter designs.

Product Introduction

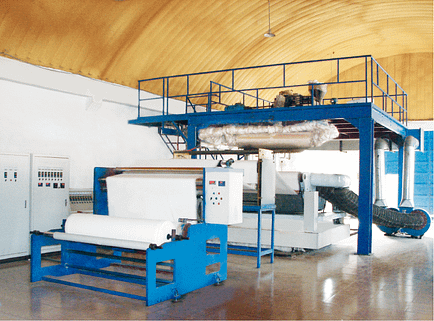

Handanhy PP melt-blown filter media is made from special polypropylene resins with unique techniques, using high temperature melt-blown non-woven technology. In particular, pleatable products have a higher tensile strength, higher break endurance and higher stiffness, which is critical in making mini-pleat filters, e.g. V-bank ventilation filters, air filters for automobile cabinets, filters for vacuum cleaners and various household filters. Our melt-blown filter media is highly efficient with a high capacity for holding dust, and also offers minimal airflow resistance. Top-class engineering provides for smooth, consistent performance.

Handanhy’s polypropylene melt-blown filter material covers a wide range of efficiency grades, F6 to Y11, for standard ventilation filters.

Product Performance

-

The product is made from harmless, eco-friendly hydrocarbons with white and light characteristics.

-

During combustion, PP produces only CO2 and water, which has little impact on the environment compared with other plastics and related materials.

-

The electrets present in PP, which enhance the capture performance of the air filters, are quite stable.

-

Poly-Propylene melt-blown filter media is majorly used in power generation, commercial and industrial sectors

-

PP is a fire-resistant material and may be used to manufacture UL-2 grade filters.

-

It is also a water repellent material, and thus less troublesome when it comes to considering microorganisms.

-

Acid and alkali resistant material, with high melting point (167-174)℃ and stable performance.

Product Technical Specification

| TYPE | BASIC W. G/M2 | THICKNESS MM | RESISTANCE PA | EFFICIENCY % | STIFFNESS MG | APPLICATION CRAA ( EN799 ) |

|---|---|---|---|---|---|---|

| HY-LZ-50 | 85 | 0.55 | 8 | 50 | 180 | F5 VENTILATION FILTER |

| HY-LZ-60 | 90 | 0.58 | 20 | 70 | 190 | F6 VENTILATION FILTER |

| HY-LZ-80 | 90 | 0.60 | 25 | 90 | 220 | F7 VENTILATION FILTER |

| HY-LZ-90 | 100 | 0.55 | 35 | 95 | 300 | F8 VENTILATION FILTER |

| HY-LZ-95 | 100 | 0.55 | 45 | 97 | 400 | F5~Y9 VENTILATION FILTER |

| HY-LZ-98 | 110 | 0.55 | 110 | 99 | 450 | F9~Y10 VENTILATION FILTER |

| HY-LZ-995 | 120 | 0.65 | 120 | 99.5 | 550 | F10~11 VENTILATION FILTER ( EN1822 H10~H11 |

Test Method: TSI 8130 NaCl, 0.3µm@32L/min, 100cm²

Test Result of Pleated Filters

| FILTER TYPE | FILTER AREA | FILTER DIMENSION | FLOW RATE | TEST AEROSOL | DUST-LOADING |

|---|---|---|---|---|---|

| Mini Pleat Filter | 18 m² | 592×592×292 mm | 3400 m³/h | DEHS | ASHRAE |

Test Standard: EN779:2012

| GRADE | F5 | F6 | F7 | F8 |

| INITIAL RESISTANCE | 46 Pa | 52 Pa | 62 Pa | 65 Pa |

| INITIAL WEIGHT EFFICIENCY | 100% | 100% | 100% | 100% |

| INITIAL EFFICIENCY ( 0.4µm ) | 40.7% | 68.1% | 75.7% | 80.2% |

| AVERAGE WEIGHT EFFICIENCY | 96.8% | 99.4% | 99.6% | 99.0% |

| AVERAGE EFFICIENCY (0.4µm)/FINAL RESISTANCE (250Pa) | 68.2% | 84.5% | 89.6% | 91.3% |

| AVERAGE EFFICIENCY (0.4µm)/FINAL RESISTANCE (350Pa) | 72.3% | 86.9% | 91.3% | 92.4% |

| AVERAGE EFFICIENCY (0.4µm)/FINAL RESISTANCE (450Pa) | 75.0% | 88.1% | 92.6% | 92.9% |

| DUST LOADING CAPACITY/FINAL RESISTANCE (250Pa) | 299.9 g | 242.1 g | 161.1 g | 197.2 g |

| DUST LOADING CAPACITY/FINAL RESISTANCE (350Pa) | 358.5 g | 297.6 g | 200.0 g | 248.8 g |

| DUST LOADING CAPACITY/FINAL RESISTANCE (450Pa) | 406.6 g | 342.3 g | 239.7 g | 296.8 g |